Assessment OICEW-1-1D

Sweat joint

Assessed in ST-0999E Sea Term I (Engineering Portion)

Condition

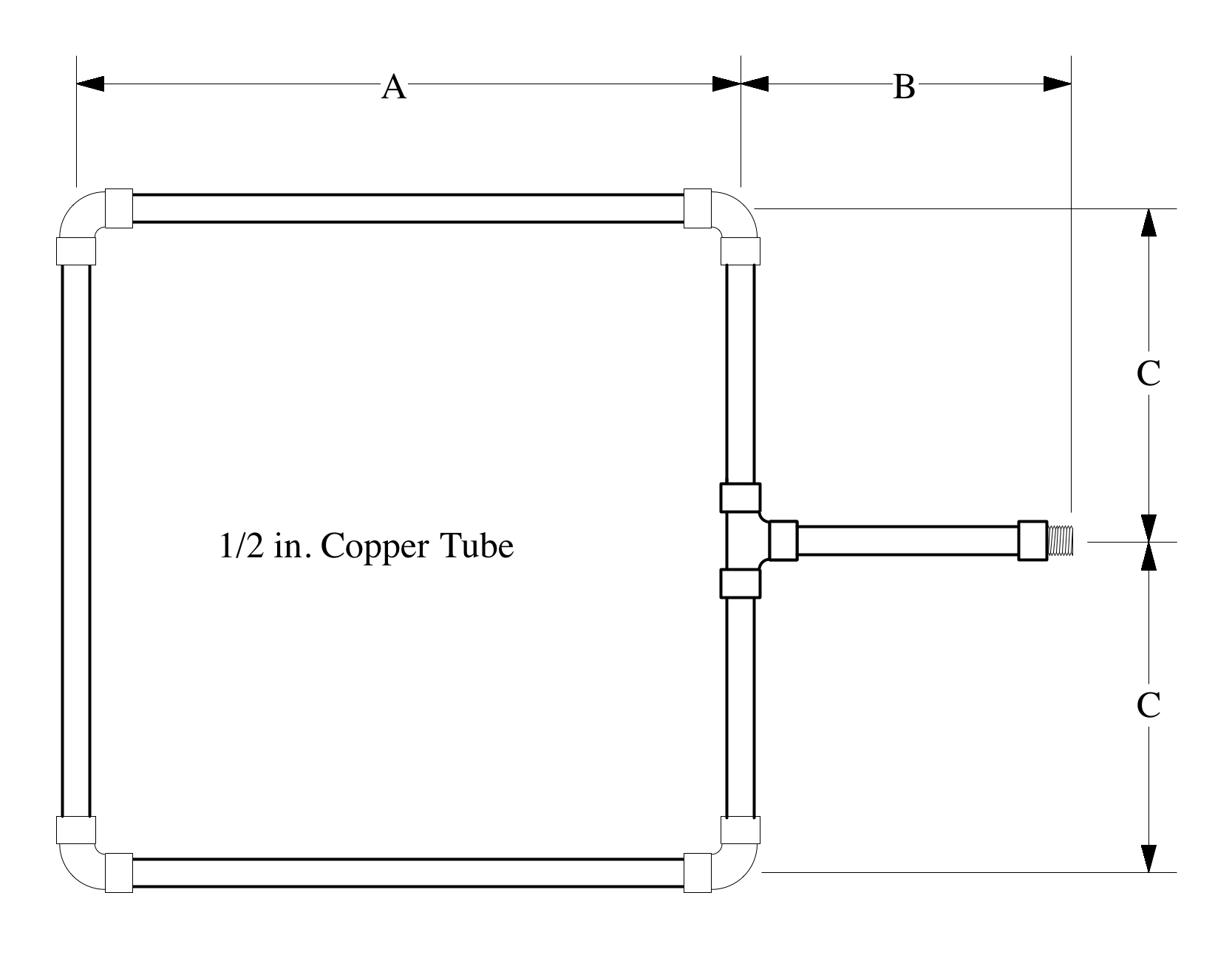

In a workshop/laboratory or other safe working environment, given proper tools, lighting, ventilation, and 1/2 inch copper tube and coupling.

Performance Requirements

| Behavior | Standard |

|---|---|

| The student will: | During assessment, the student shall, at a minimum: |

|

Plan fabrication of sweat joint fitting | |

|

Use:

Prepare joint by cleaning and fluxing | |

|

Test joint for tightness |

Prove joint leak free |

Attachment:

Supports Table A-III/1 officers in charge of an engineering watch

| Competence | Knowledge, Understanding & Proficiency | Task |

|---|---|---|

|

Appropriate use of hand tools, machine tools and measuring instruments for fabrication and repair on board |

C1.6 Use of hand tools, machine tools and measuring instruments |

Sweat joint |

Published: 2016-10-28-04:00